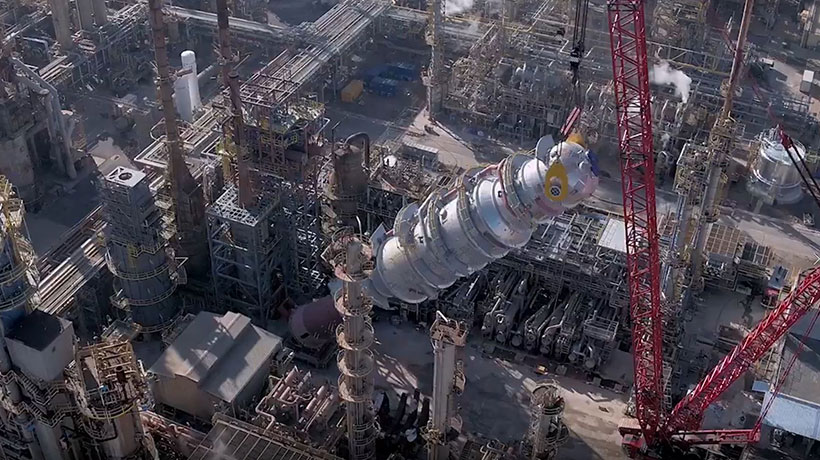

Watch how we got the new vacuum distillation tower at our #Castellón refinery in Spain into place

Posted by BP on Saturday, March 17, 2018

Client: BP CASTELLON (SPAIN)

Project Name: VACUUM UNIT REVAMP

Locations: SOUTHERN SPAIN

Scope of Work description:

A Peer Review Report was commissioned by BP Oil España (BP) and prepared by Lowther-Rolton to assess the Heavy Lift and Transportation (HLT) planning issued by BP and Technip during the DEFINE stage of the VDU Project at BP Oil España’s Castellón Refinery in the province of Castellón, Spain together with information presented by Technip at the Peer Review meeting convened during 02 February 2016.

The Project goal was to install the Vacuum Tower fully assembled, in order to reduce work conducted at height and in the process unit, Additionally, the work took place at the center of an operating Refinery, incurring multiple process hazards and high potential consequences should an incident occur.

The Vacuum Tower was the most complex heavy lift for the Project and Lowther-Rolton’s services were again called upon to provide a fully independent technical audit of the proposed lift method with on-site attendance to verify all operational activities were completed in line with the L-R’s authorised lift plan and method statements.

The Vacuum Tower, T2101- Y weighing 600Te had an overall length of 57.85m and was to be positioned on a 2.25m raised Concrete entablature. The shell diameter of 9.1m, with an overall width of approximately 14.5m over dressed platforms.

The Liebherr LR 11350 was rigged on SDBW configuration with a 78M Main Boom and 42m Backmast utilising 300Te of counterweight and an additional 600Te of derrick counterweights at a radius of 25.0m with this configuration a lift capacity of up to 881Te at the landing radius of 20m was achieved.

During the detailed technical audit of the contractors lift plans L-R brought to the attention of the client and heavy lift contractor areas that required further detailed appraisal and indicated probable foul points during the upending operation that were not previously documented and managed, each of these having the potential to cause major implications during the raising of the Vacuum Tower. L-R advised additional control measures to be incorporated, which were subsequently included within the contractors existing lift plans. An example of these was control measure to monitor and subsequently minimise the horizontal forces being transmitted into the temporary tailing frame, additionally a method was devised for removal of the four large transportation saddles positioned under the Vacuum tower during the lifting process which prevented the need for personnel to be in the line of fire in and around a suspended load whilst upending and tracking with the Main lift crane.

The additional methods L-R employed assisted in minimising the actual time the Tower was on the hook of the main lift crane from initial Lifting, upending and position on foundation and greatly assisted in a safe and successful lift being achieved.