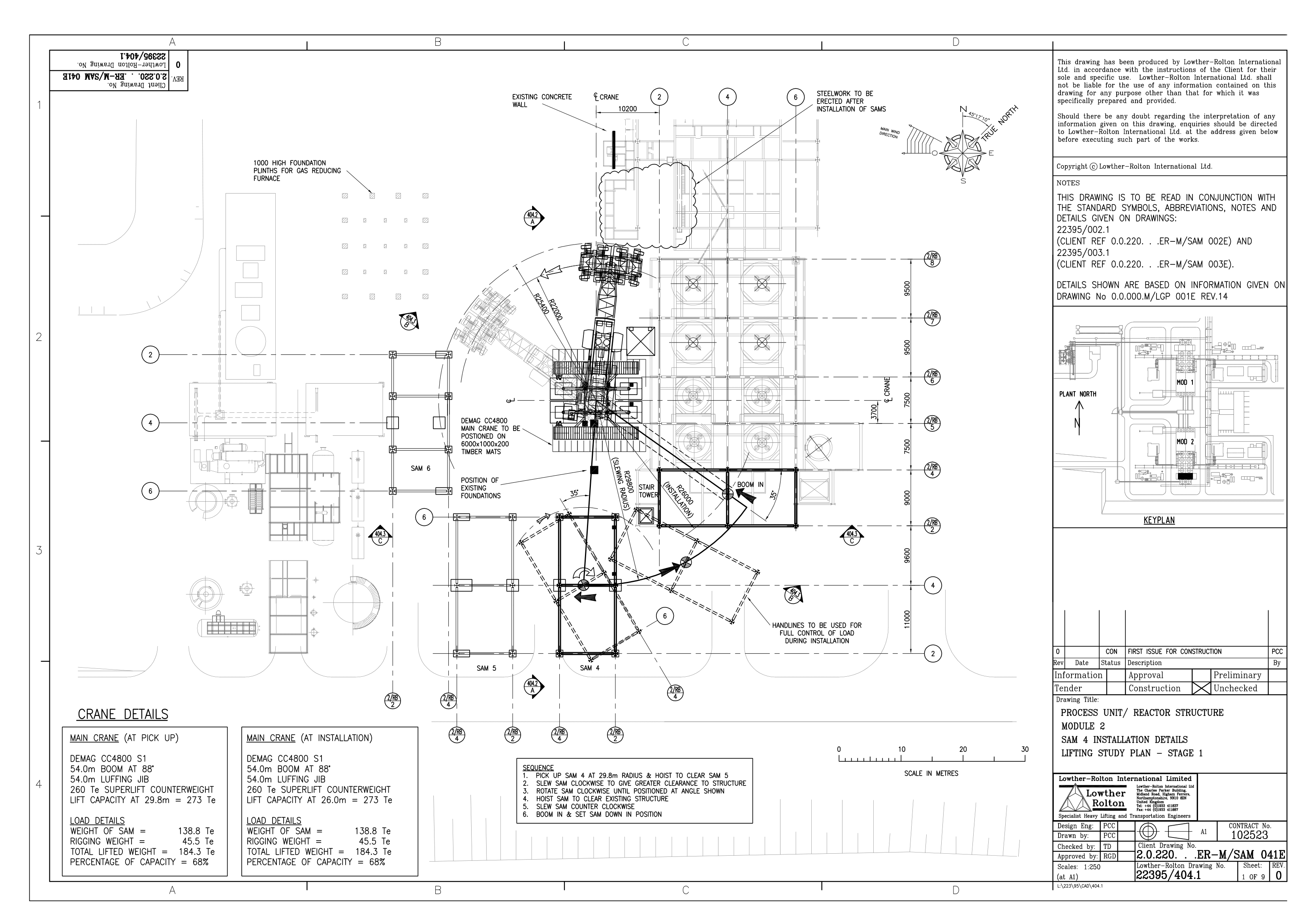

How Lowther-Rolton Guides Your Transport and Heavy Lift Project from Beginning to End

Ensuring a project runs smoothly requires experienced and informed decision making from the get-go. This article will provide information about how Lowther-Rolton can leverage vast